Tooling, machine design/build/repair.

A collection of custom tooling and machine repair I have completed for past jobs.

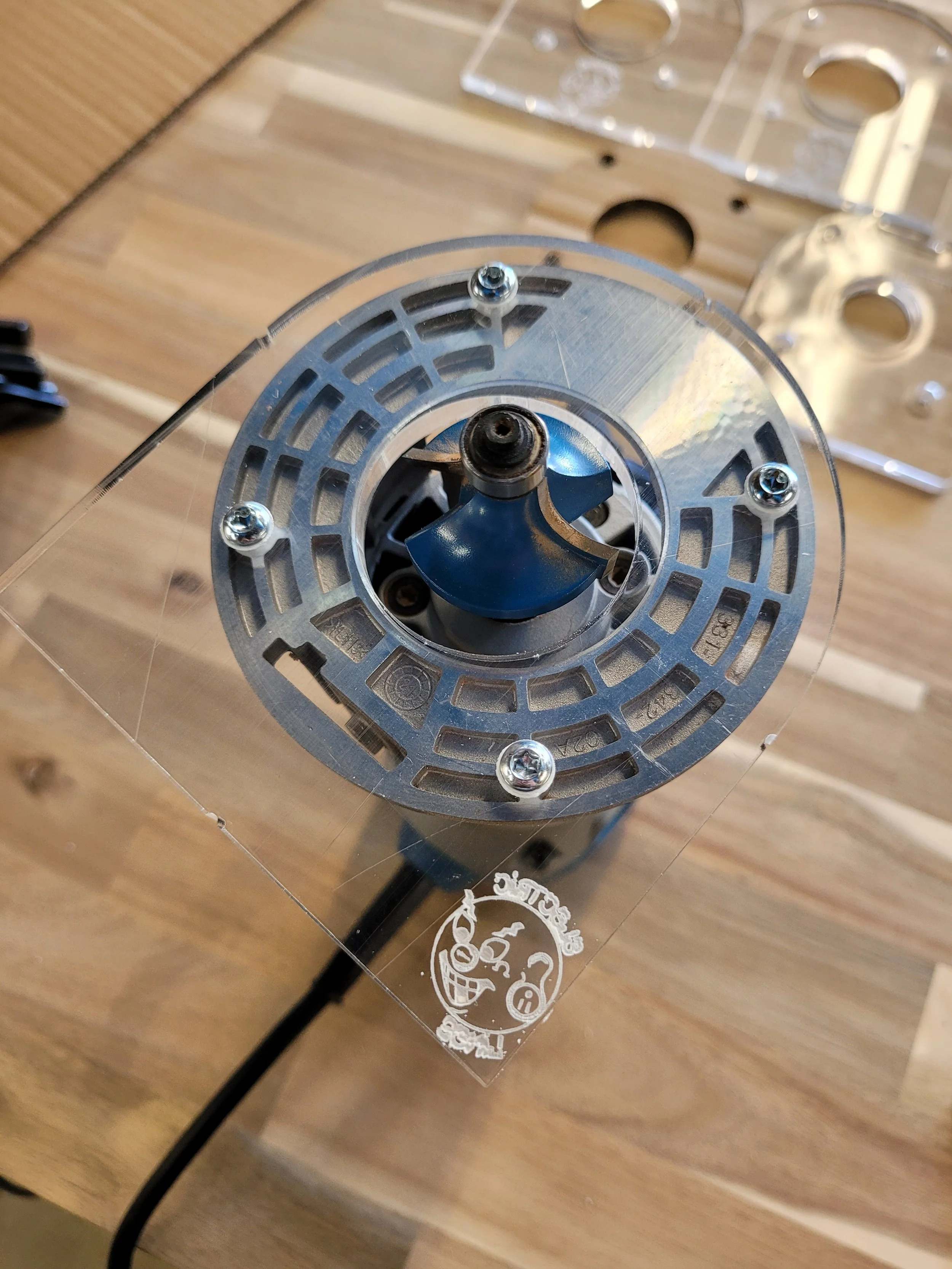

Custom Router Base Plate

This router plate is designed to fit larger router bits. The original plate did not allow the use of a chamfer bit that was sold as apart of the set. The new plate features a larger center hole for cutting bit clearance, improved guide notches, and the Electric Lines logo etched into the plate.

Scope:

Design

Reverse engineer OG Plate.

Make corrections

Programming

Create DXF and G Code.

Make

Cut and Engrave on 100w Laser.

Requirements:

Match overall dimensions.

Match bolt pattern.

Clearance hole for large cutting bits.

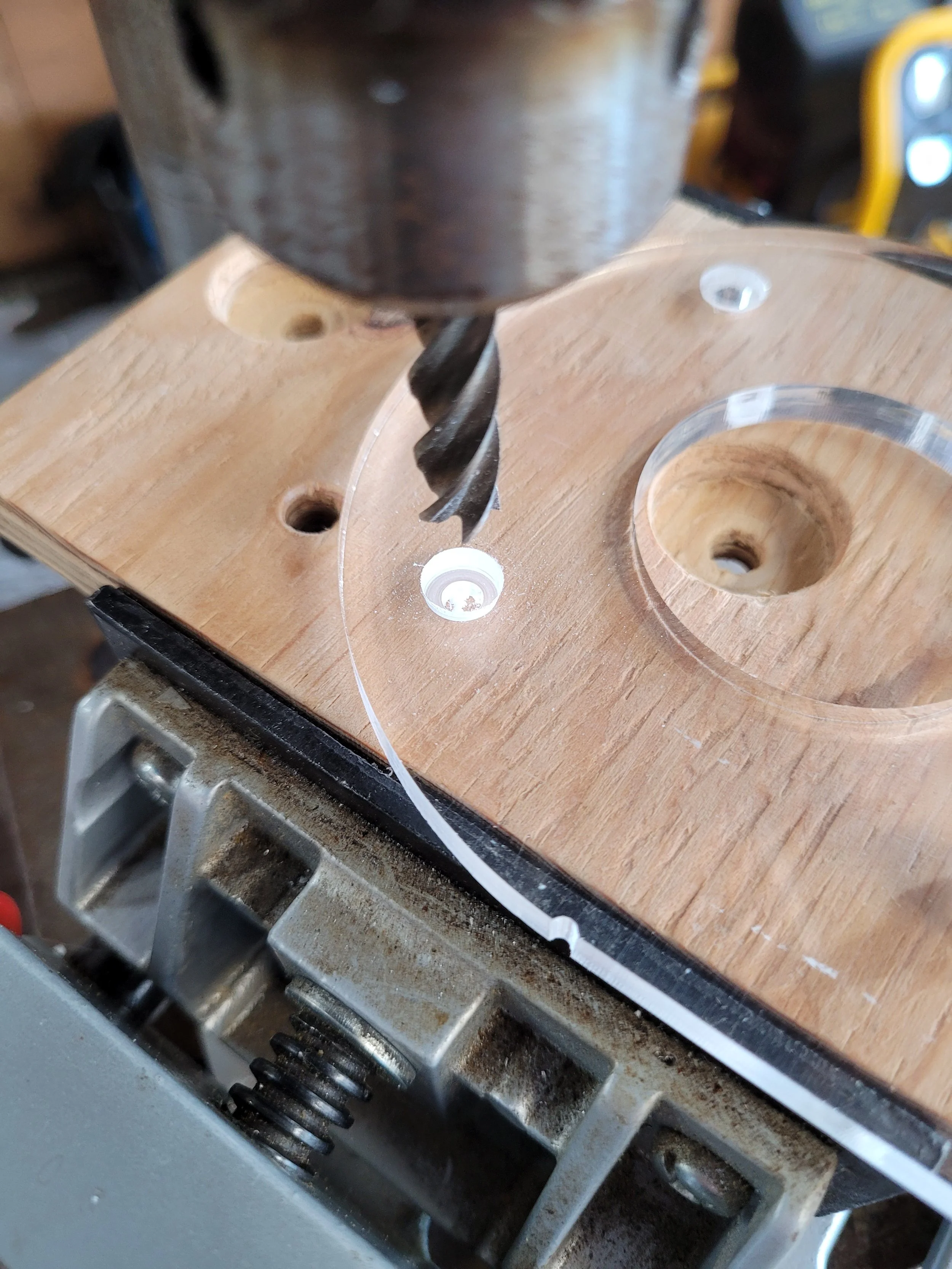

Grizzly G0768 Lathe Repair

I purchased a used Grizzly G0768 Lathe on Craigslist for a contract. The project was to machine and assemble latch mechanisms for Amazon Kuiper. Half way through my fist run, the spindle stopped rotating. After troubleshooting and express shipping I was swapping the motor to finish the project on time.

Scope:

Trouble shoot machine issue.

Order parts.

Successfully swap/ install new parts.

Requirements:

Replacement motor.

Identical power rating.

Identical bolt pattern.

Testing the new motor.

Testing control system after motor replacement.

Goals:

Limit air exposure

Incorporate emersion heater

Home Brew Pasturization System

My wife and I are amature mead and wine brewers. In an effort to finish batches quickly and safely I developed and built a pasturization system to aid us in our brewing process.

Concept: Design a system to pastruize 5 gallon batches of wine/ mead at one time.

Requirements:

Meet WA LCB Pasturization requirements.

140*F for 30min

160*F for 15sec

Use home brew/ food safe materials

Material props must beat Temp requirements.

Materials must perform underwater.

Design for in house MFG capabilities.

Scope:

Design System

Submersible coil

laser cut frame

Select tubing

Heat bath

Select COTS

Flow process

Purchase Materials

Program laser cut parts

Build system

Test

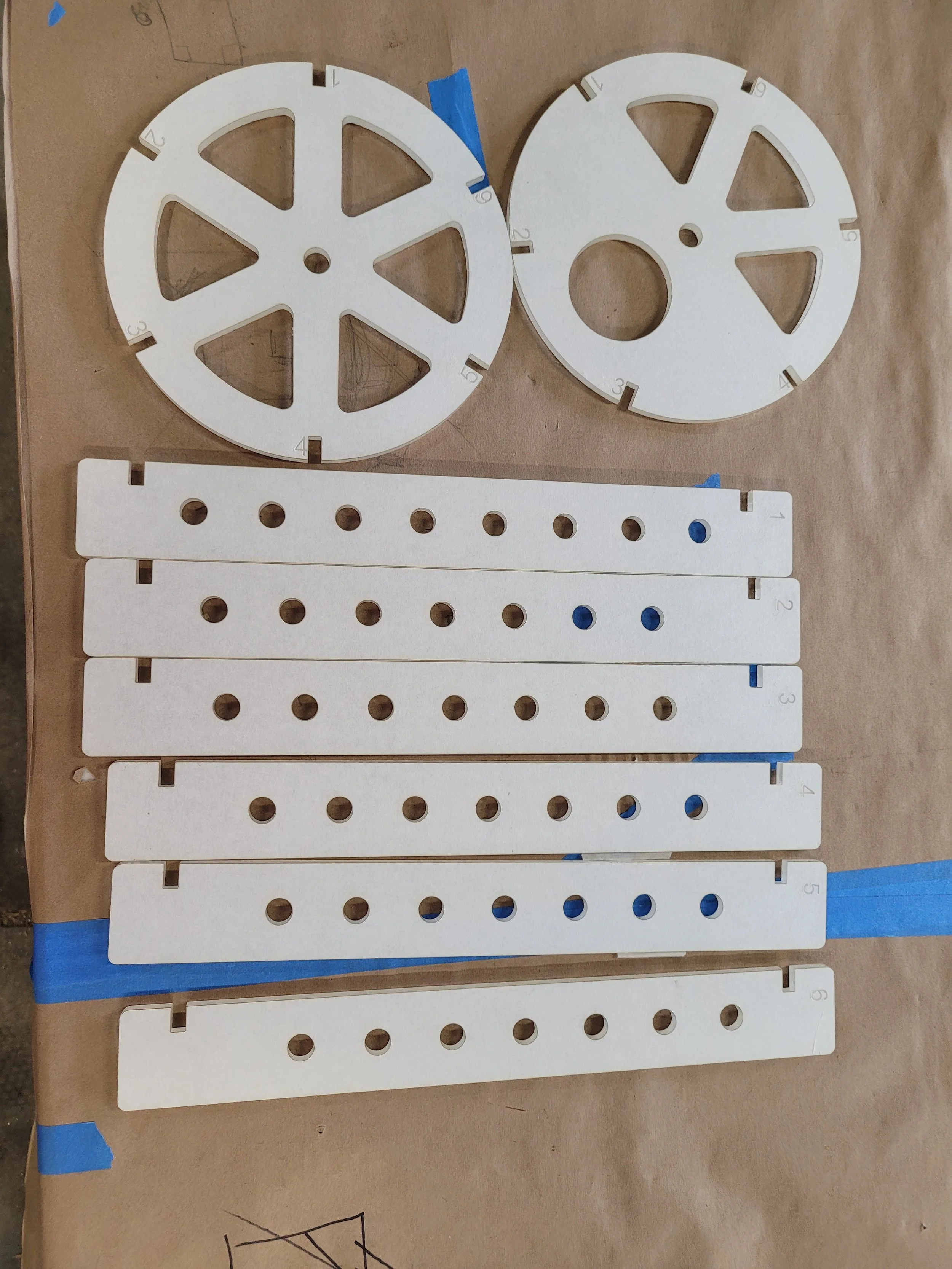

3D Printer Spool Holder

The Dremel D2 printers are designed to hold dremel brand filiment spools inside the print cabinet. In order to use industry standard filiment spools I had to develop and install new spool holders.

Scope:

Design spool holder

Program laser cut parts

Run parts

Laser cut frame

Turn mandrel

Assemble

Requirements:

Footprint must fit inside printer cabinet.

Material must fail or deform under the ambient temperature inside the cabinet while printing.

Lawn Mower Repair

The bracket that supports the carburatuer and choke asm on my lawnmower sheared and left the assembly dangling.

Scope:

Remove broken bracket

Fixture

Clean, weld, paint

Install bracket

Install components